文字のサイズ

- 小

- 中

- 大

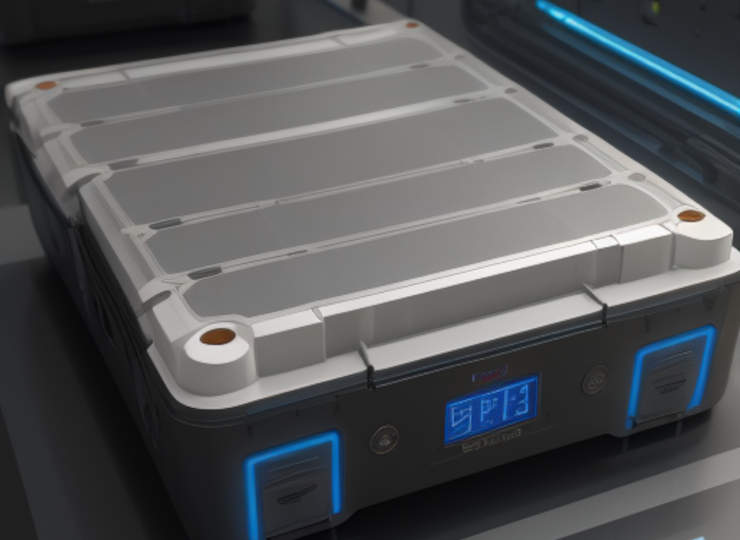

Battery cells are becoming more efficiency- and safety-oriented

The thinking around battery cells for BEVs is changing.

Until now, the main focus of major OEMs’ thinking on battery cells has been on ‘cost performance’. With the increasing use of LFP batteries, mainly by Chinese battery manufacturers, the average price (market price) of battery cells is rapidly declining. However, compared to the speed at which cell costs are falling, the cost of pack standards is unlikely to fall. This is due to ‘efficiency’ and ‘safety’.

‘Efficiency’ refers to performance, which includes factors such as cruising range and reduced charging times. The focus is on how efficiently the cells are used. Optimising the cell’s performance by optimising the cell’s operating environment is a key area of focus when packaging.

‘Safety’ includes ‘crash safety’ and ‘fire safety’. ‘Crash safety’ refers to how safe the battery pack is from collisions with vehicles and objects, while ‘fire safety’ refers to how well the battery cells are protected from ignition and fire spread from thermal runaway and external fires.

In addition to crashes involving the battery pack itself, a number of fire-related incidents have been reported in BEVs. For this reason, major OEMs need to carefully consider the design and construction of battery packs as an important axis in creating BEVs that can be used safely, in order to appeal to the demand segment considering BEVs. Reflecting these various factors, the development and mass production of battery packs has offset the effect of lower cell costs, despite the initial reduction in cell costs. Instead, costs may rise above industry expectations on a pack basis.