文字のサイズ

- 小

- 中

- 大

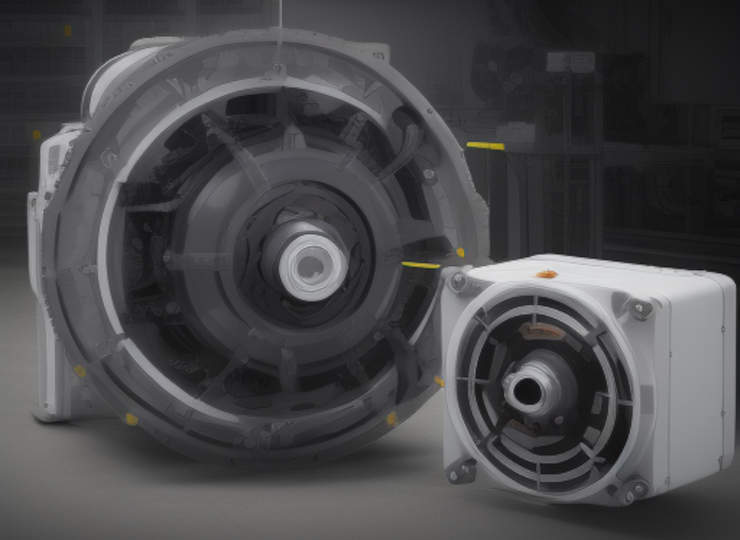

eAxle’s Tier 1 supplier presents wire-wound field motors at CTI, Germany.

At the CTI Symposium Berlin (CTI) in December 2023, all major eAxle Tier 1 suppliers have presented wire-wound field motors (EESM).

Permanent magnet synchronous motors (PMSM), which use permanent magnets, are said to be superior in terms of motor performance and efficiency, but engineers at the technical symposium are still focusing on the ‘HRE (heavy rare earths) procurement issue’ and ‘cost reduction’. In recent years, concerns over rare metal export restrictions, particularly in China, and the impact of trade and localisation regulations such as the IRA in the USA, have meant that emphasis must be placed on stable procurement in the manufacture of drive motors, and attention is being drawn to motors such as Low-HRE and HRE-Free.

In response to the above-mentioned changes in the political and trade environment, Magna, ZF and BorgWarner, which have been involved in motors based on PMSM, presented EESM-related concepts and technologies at the CTI. Vitesco, which will soon mass produce the new eAxle, also mentioned that EESM will be applied as an option in its main PMSM, while OEMs BMW and Nissan, which are already using EESM, as well as Renault will also be using EESM for their BEVs.

The Electric Vehicle Component Supply Chain and Competitive Landscape series examines and analyses the relevant component industry, including the business development and competitive landscape of Tier 1 and Tier 2/3 suppliers for key components related to the global electric vehicle (xEV) motor/inverter.

It will also report on the challenges in the xEV motor and inverter industry and related component industry through a survey of internal and external literature and direct interviews with industry players. This basic information is indispensable for the formulation of electrification business strategies for automobile manufacturers, automotive components and materials manufacturers.